|

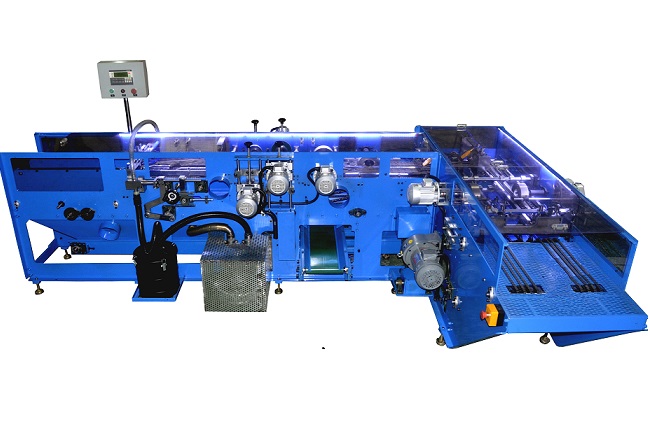

| name:Automatic Plate Saw Slitting Machine |

| Product information: |

FUNTION

1.The machine fit for the plate length ≤380mm,width ≤330,the thickness between 1mm-5mm;

2. Roll forming cut, high precision, no waste;

3.Vacuum can automatic adjust accord the machine run speed;

4. PLC control, high reliability, easy maintenance;

5. Longitudinal and transverse conversion adopt patent technical, fast and stable, cut speed can up to 60-100

pieces per minute;

6. The run channel adopts the up and down seal technical;

THE DEVICE BASICALLY COMPOSED

1, The device configuration

Control cabinet, feed material system, vertical roll cut system, transverse roll cut airframe, power plant,

brushing and roller cutting head, the plate receiving system, the waste collection system.

2, The number of device configuration

(1) Control cabinet: 1.

(2) Feed material head: 1.

(3) The longitudinal roll cut body: 1.

(4) The lateral body roll cutting: 1.

(5) Brushing nose:6.

(6) Roller cutting head: 7.

(7) Plate rewinding device: 1.

3, Device configuration content

(1) Control cabinet: PLC, text display, solid state relays.

(2) On the material head: Rack, vacuum, power connection device, the sending device, sucker.

(3) Vertical roll cut body: channel steel, steel plate, stainless steel rails, brushing nose, cut off the

head, roller cutting head.

(4) The lateral roll cut body: channel steel, steel plate, stainless steel rails, roller cutting head.

(5) Power plant: steeples gear motor, carbon steel chain, guide device.

(6) Brushing nose: Import roll cutting machine for brushing round brush photoelectric machine.

(7) Roller cutting head: the precision alloy blades, high-precision transmission mechanism.

(8) The plate receipts device: counting sensors, conveyor belt, motor speed.

(9) The waste collection system: the sealing channel, the blade means or belt conveyor means or hopper

means, pumping dust inlet.

(10) Operating procedures: artificial feeding → material → sucker brush ears→ vertical plate saw cut

→ horizontal saw cut → automatic pack output (count) → shearer manual receipts into the box or

transferred to the next process .

EQUIPMENT SPECIFICATIONS INDEX REQUIREMENTS

1.Equipment Specifications Model: PCM-0403201

2.The plate length ≤380mm,width ≤330, thickness: 1.0-5.0 mm,(specifically plate should provide the

buyer drawings first)

3.Cut plate thickness: 1-5mm.

4.Production speed: ≥ 80 pieces/min

5.The rejection rate:≤ 1. 0%, the premise of the buyer to provide the plates of the deformation is

not greater than 0.5mm.

6.The guide device adjustable plate length range: 160-380 mm (Specific buyer provides drawings first.

7.Saw bit specifications: φ150.3Xφ50X2.0mm

8.The main chain Specifications: Pitch 25.4X17.

9.External pumping dust interface size: φ148mm.

10.The main motor specifications: gear motor power 2.2KW deceleration 1/30.

11.Power supply: Three phase AC380V±10% 50Hz

12.Negative pressure parameters: maximum flow rate≥250m³/h vacuum degree≤ 100KPa

13. Total weight: 3.0 T

14.Equipment Dimensions (L x W x H mm): Roll cutting machine dimensions: 5680 x 1800 x1400 receipt laminations

dimension 2030x 850 x 680mm;

Control cabinet dimension: 660 x620 x240mm;

15. Device color: gray and black.

16.Working hours: 24 hours continuous work properly. |

|

| Product Parameter : |

|

Model

|

Input Voltage

|

Input Power

|

Fit Plates

|

Slitting Size (mm)

|

|

PCM-0403201

|

Three Phase AC380V±10% 50Hz

|

8KW

|

Double Plates/Four Plates

|

315×160×3.2

|

|

Slitting Thickness (mm)

|

Slitting Speed

|

Brush Lug Width(mm)

|

Slitting Plate Accuracy(mm)

|

Cutter Range

(mm)

|

1.5~4.0

|

60~100 Pannels/Min

|

8~20

|

0-1mm

|

Up Down (Adjust):0-10

Front Back (Adjust):0-10

|

|

|

|

站頭.gif)